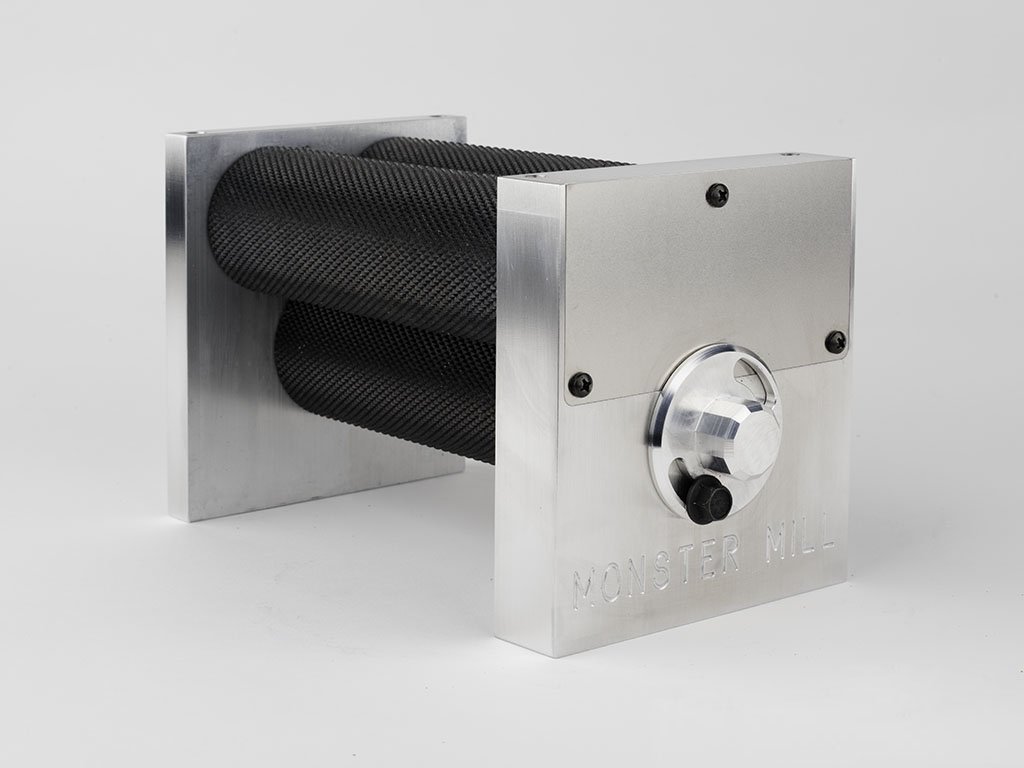

Geared 3 Roller Pro Brewer Grain Mill

Geared 3 Roller Pro Brewer Grain Mill

Share

Couldn't load pickup availability

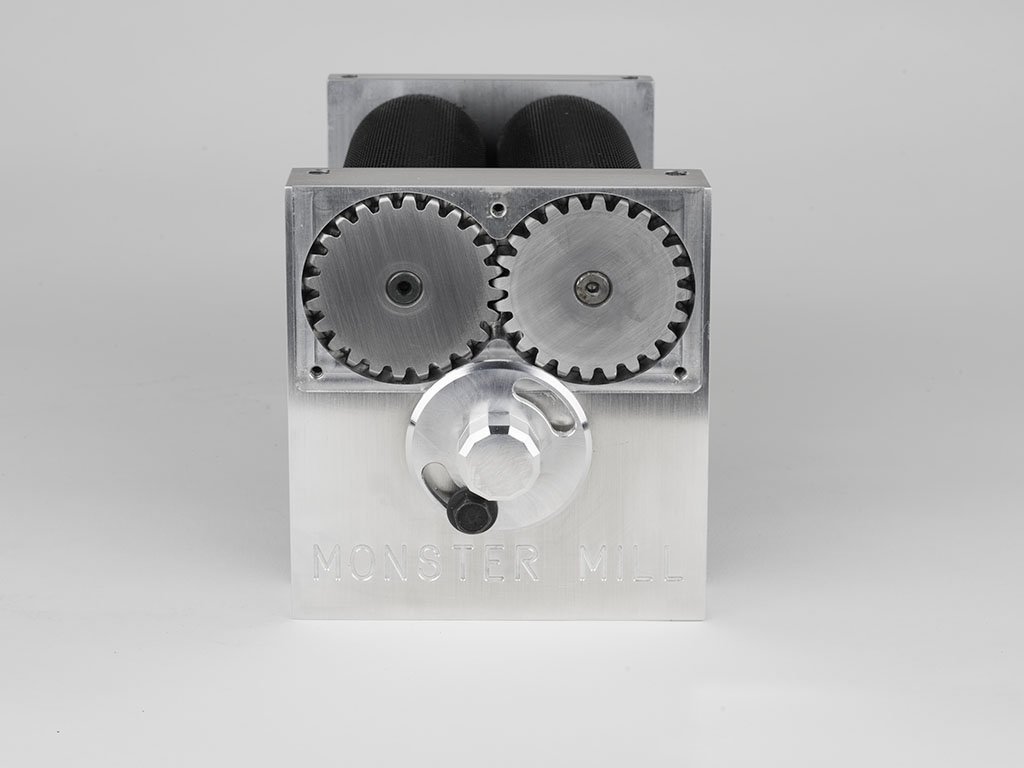

Its finally here. We have added gears to the already successful MM-3Pro to create the new MM-3ProG. DO NOT run this mill backwards under any circumstances, you MUST turn the drive shaft ONLY clockwise to feed grain down into the gap. The drive shaft spins one top roller that drives the other top roller through a set of alloy steel gears. Grain from the top fixed gap is force fed to the adjustable gap between the main drive roller and the bottom third roller. Super reliable feeding is now a given for your small commercial brewery, or hard core homebrew operation. The largest and most advanced in our line of 3-Roller Monster Mills, The MM3-ProG is a further upgrade of our already successful MM-3Pro. The MM-3ProG comes standard with two 1215 alloy steel gears driving two 2" diameter heat treated steel rollers, with a third idler roller providing a second crush through an adjustable gap, billet aluminum knobs, as well as the 1/2" drive shaft with three flats for drill drive. These rollers have girth, as well as length, 6" to be exact. With all the great features of our already popular MM-3Pro, but with gears for positive feeding. The MM3-ProG crushes all your grain twice, with one pass through the mill. It starts with a preliminary crush through the initial fixed gap of 0.070” between the top two rollers, and then ends with a pass through the adjustable second gap (0.028->0.055) between the drive shaft roller, and the bottom third roller. The initial pass slightly flattens the grain, and gets it ready for the next crush, that breaks apart the grains and loosens the starch with minimal husk damage.

The MM-3ProG consists of 6061 aluminum block frames with three 6" long 2" diameter steel rollers riding on Oilite™ oil impregnated bronze bushings, while the third idler roller rides in bushings that are offset mounted in an adjustable knob. The billet knob is held in a fixed position by a black oxide bolt you can loosen to adjust the mill. This system provides an adjustment range of .027". The knobs are milled from solid 6061 aluminum barstock for excellent durability, and now ride in Igus™ bushings to prevent galling between the knob and frames. The flange has two semi-circular slots that allow you to attach the knob positively to the face of the aluminum frame. They have 12 sides for a positive grip. For the rollers we use a superior grade of steel that is much harder (1144 alloy) than what is found on most comparable products and then we induction harden the rollers so that they will last 10X as long. Commercial brewers have crushed 200,000 lbs + . The drive shaft, and all the axles are integral to the roller rather than screwed into the ends. All the axles are 3/8", with minimal freeplay in the bushings. This mill is massive and comes standard with the 1/2" drive shaft. We offer an optional keyed 1/2" drive shaft for gear motor/coupler applications. Instead of three flats for your drill chuck, there is a small slot for a 1/8" key to completely eliminate slipping in gear motor/coupler applications. You will need some POWER to turn this mill. Suitable for a small micro, and great for the home brewer that wants the best, the MM3-ProG is our flagship model, the best of the best.

We highly recommend that you purchase our base and hopper. All current bases come standard with precision drilled alignment holes, dowel pins, and matching holes in all our Pro Frames, as well as the smaller MM-3 mill. To take advantage of this feature, you need to purchase our base and hopper along with your mill for precision frame alignment, and superior roller motion. You'll also need a high quality corded drill to drive this beast. We recommend a 1/2" drive name brand corded drill. Please note that the larger shaft will require the larger 1/2" drive drill, as the more common 3/8" chuck won't accommodate the larger shaft. Our hand crank does NOT fit this mill as supplied, nor is it recommended for any of our Pro series mills.

This mill will NOT mill corn and doesn't work well with rye by itself. It is designed for barley and wheat malt, and un-malted wheat. For corn see the 2Pro, or the 2ProPD.

Specifications:

6" Long Adjustable Gap:

- top two rollers both driven by 1215 alloy steel gears

- grain driven third roller with fully adjustable gap

- three six-inch steel rollers form two gaps, a preliminary fixed gap of approx .070", and a fully adjustable secondary gap

- dual eccentric adjusters: 0.028 to .055" secondary gap - milled from solid 6061 billet aluminum

- Igus™ bushings on both aluminum knobs to prevent galling

- 3 x 6" long, 2" diameter 1144 alloy heat treated steel rollers

- drill-drive – gear motor drive

- 12 lbs/minute throughput at 240 rpms

- 6061-T6 aluminum alloy frames

- Oilite™ oil impregnated bronze bushings for the axles

- 1/2" integral drive shaft standard w/3 flats for drill driving, 2" long outside frame

- Optional 1/2” integral drive shaft with 1/8” keyway for direct drive with a coupler

- 3/8" integral axles

- 97.5 mm shaft height to match our gear motor (3.839 inches)

Instructions

Mill Instructions (pdf)

Hopper Assembly Instructions (video)